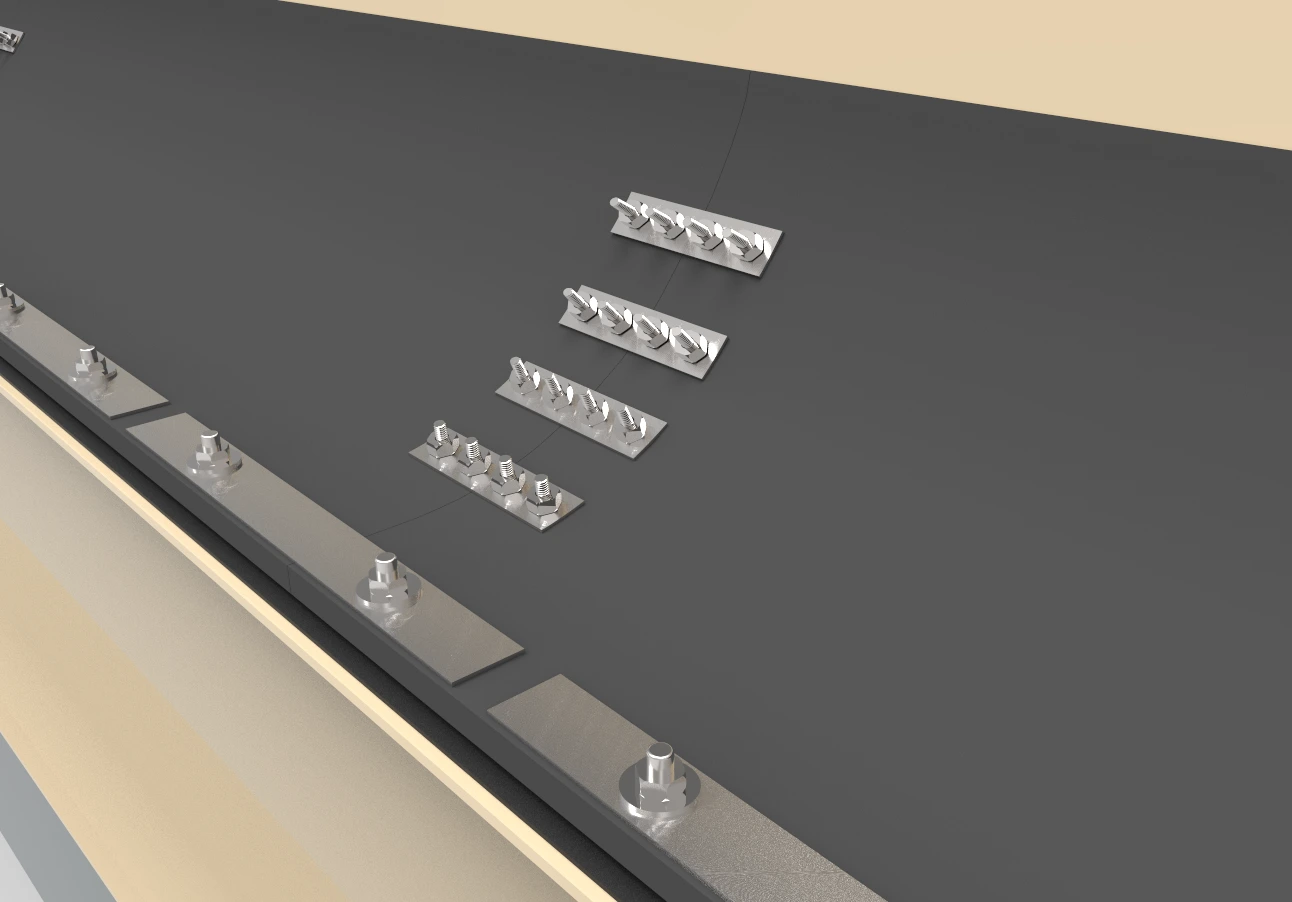

SECONDARY WIPER SEAL

TankSeal®WPR

GENERAL INFORMATION

The Wiper Seal is designed to prevent product loss and atmospheric contamination from Internal Floating Roof Tanks (IFRT) and to ensure effective operation in specific tank conditions.

It can be used for aluminum and carbon internal floating Roofs.

BENEFITS

- In – service installation

- Complying with EPA Requirements

- Used in internal roofs in compliance with API 650

- Suitable for welded and riveted tank shells.

- Compatible with stored products

- Maximising usable tank capacity

- Primary fabric seal (selected for mechanical durability and chemical stability with the product)

- Easy to install, repair, inspect (all components are accessible from above)

WIPER MATERIAL

PVC / Nitrile

- Material seal: Nitrile / PVC

- Exceptional chemical resistance to alcohol, ethanol and other special applications.

- Excellent flexibility and abrasion resistance.

- Temperature range: -10 to 105 ° C

- Standard dimensions: 310mm (L) x 13-4mm (T)

XLPE

- Material seal: Crosslinked polyethylene XPE

- Exceptional chemical resistance for alcohol, ethanol and other special applications.

- Excellent flexibility and resistance to abrasion.

- Temperature range: -60 to 80 ºC

- Standard dimensions: 310mm (L) x 20mm (T)

URETHANE

- Material seal: Urethane

- Exceptional chemical resistance for MTBE and 100% aromatics.

- Excellent flexibility and resistance to abrasion.

- Standard dimensions: 300mm (L)

- Temperature range: -30 to 60 ºC

STANDARDS

API-650 Ap. G

NFPA “National Fire Protection Agency”.

AISI Stainless Steel Cold Formed Structural Design Manual.

AWWA D-100.

EUROCODE

TECHNICAL DATA

- Rim Spaces: Normally 200 mm. ± 100 mm. is the standard but the seal design can be modified to suit larger nominal rim space.

- Aromatic Service : 100%

SEAL SPECIFICATION

-

Service life: 10 years

-

Typical Weight: ≈ 5-8 kg per linear meter.