API FLOATING COVERS

TankCover®

GENERAL INFORMATION

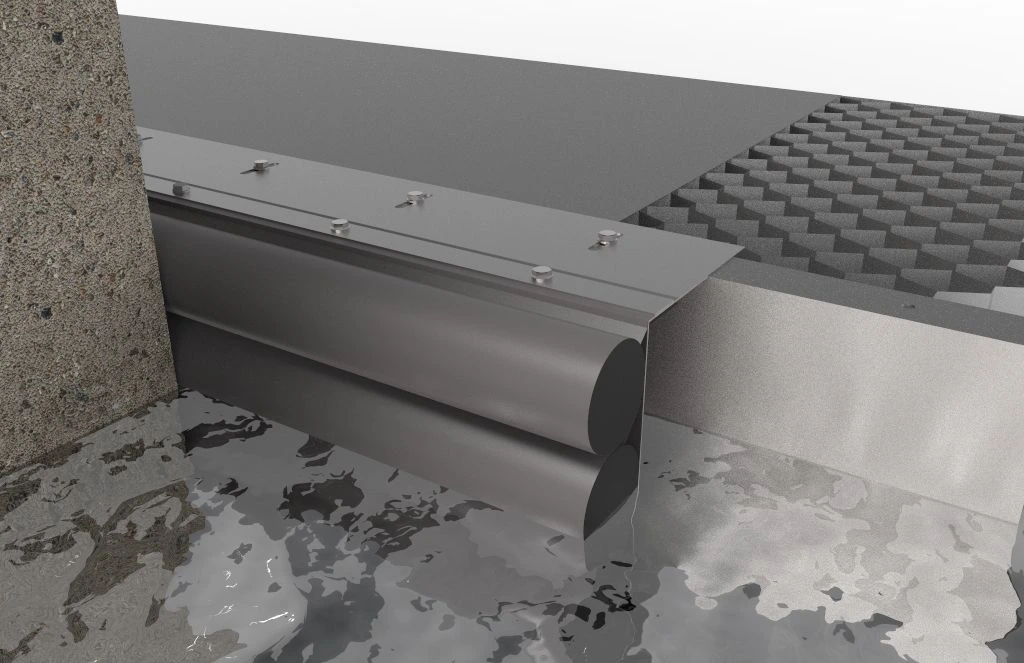

These covers are a breakthrough in the covering market, mainly destined to cover water-oil separator systems (API) and other installations. They can be fixed or floating.

Its design incorporates the latest technological advances resulting a cover with higher performance properties without the necessity of maintenance and increasing its useful life.

The robustness of these covers is unmatched in the industry prevent or minimize the emissions to the atmosphere.

This floating covers are designed to satisfy the necessities of the strict environmental requirements of today. They are designed to satisfy and to comply with the various environmental and industry, local and international, performance standards. All the metallic parts that are in contact with the product are of aluminum covered with epoxy resin or stainless steel.

The cover is designed to support with security at least two persons on any place of the roof while the roof is floating or resting on its supports without damaging the cover and avoiding that the roof sinks and the product gets on the cover.

BENEFITS

- Designed to be in contact with the entire surface of the liquid.

- Unmatched higher strength.

- Unsinkable design and construction.

- All components and connections are vapour tight.

- Maintenance-free design.

- Resistant to almost all industrial residual liquids.

- Resistant to UV rays and to the ozone.

- Long useful life.

- Easy installation.

- Double sealed.

- Air battery wire to earth.

DESIGN & CONSTRUCTION

This type of Full Contact floating cover is constructed with aluminum material or with plastic material reinforced with glass fiber and designed for adverse operating conditions. The individual panel sections are ribbed for additional strength and durability.

All the compartments of the panel are fitted with test ports to ensure that each compartment is free of hydrocarbon vapors.

The floating compartments of each panel are designed to make these covers almost unsinkable. The patented panel connection system facilitates a “quick and easy” field installation process. The panels are made of aluminum with a sheet and an internal honeycomb structure; A5052. Internally they have an adhesive epoxy resin and externally they are sealed with polysulfide.

The advanced aluminum materials are designed to resist almost all kind of substance contained in the Oil-Water Separators. All the materials used for the construction of the panels are resistant to UV rays and to the ozone and they are designed to provide a large useful life without necessity of maintenance.

STANDARDS

API-650

NFPA “National Fire Protection Agency”.

AISI Stainless Steel Cold Formed Structural Design Manual.

AWWA D-100.

EUROCODE

ACCESSORIES

The API covers are custom engineered to accommodate a wide variety of shapes and spans, and address entry, maintenance or other requirements (a wide range of accessories including seals, vents, supports, hatches are available to meet the customer’s needs).

APPLICATIONS

- API pool covers.

- Water pool covers.

- Reduccion of emmision to atmosfere.