PRIMARY GRAVER SEAL

TankSeal®GVR

GENERAL INFORMATION

The Graver Primary Seal GVR ®can be used on either external floating roofs or internal pan decks. This seal design has been used on tanks of long range of diameters, containing the full range of Crude and Refined products, though it is not generally used with Waxy Crudes.

BENEFITS

- In – service installation

- Complying with EPA Requirements

- Used in internal roofs in compliance with API 650

- Unique design proved by extensive mechanical testing (e.g. evenly distributed pressure)

- Suitable for welded and riveted tank shells.

- Compatible with stored products

- Maximising usable tank capacity

- Primary fabric seal (selected for mechanical durability and chemical stability with the product)

- Easy to install, repair, inspect (all components are accessible from above)

DESIGN & CONSTRUCTION

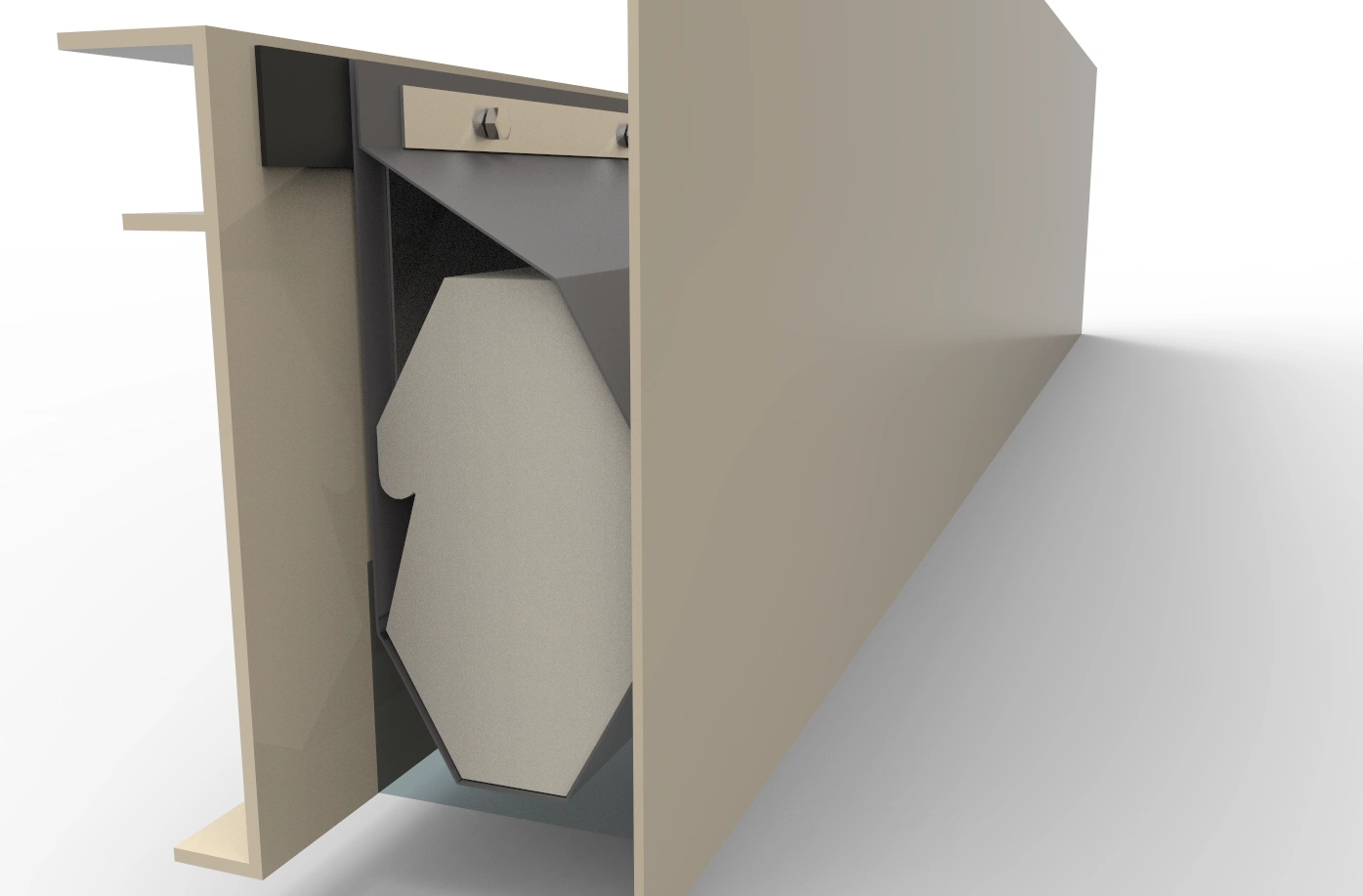

The seal is designed to enable installation and removal to be carried out from the top of the roof.

The sealing effect between the roof and the tank shell is achieved by the use of special octagonal foam sections.

The foam sections are held in position by an internal hold-down plate.

The position of the seal in service i.e. whether it is in contact with the stored product or, held above the stored product is determined by the top bolting position.

The hold-down plates and foam sections are encapsulated within a synthetic rubber seal-envelope. The seal envelope is produced from a highly abrasion-resistant coated fabric material to obtain an efficient soft sealing effect.

Weather shields can be installed as illustrated to help reduce the amount of rainwater entering the product, although in recent years it has proved more practically and economical to fit Secondary Seals.

When the Graver Foam Seal is product-mounted, i.e. installed with the stored liquid, the sealing efficiency is very high.

STANDARDS

API-650 Ap. G

NFPA “National Fire Protection Agency”.

AISI Stainless Steel Cold Formed Structural Design Manual.

AWWA D-100.

EUROCODE

TECHNICAL DATA

- Rim Spaces: Normally 200 mm. ± 100 mm. is the standard but the seal design can be modified to suit larger nominal rim space.

- Aromatic Service : 100% (some specialist chemicals may require modified materials).

-

Service life: 8 – 20 years.

-

Typical weight of complete seal: 20 kg per linear meter.

MATERIAL SPECIFICATION

- Polyurethane Coated Nylon fabric 1.0 mm. thick.

- PVC Nitrile elastomer coated Nylon fabric 1.5 or 2mm mm. thick.