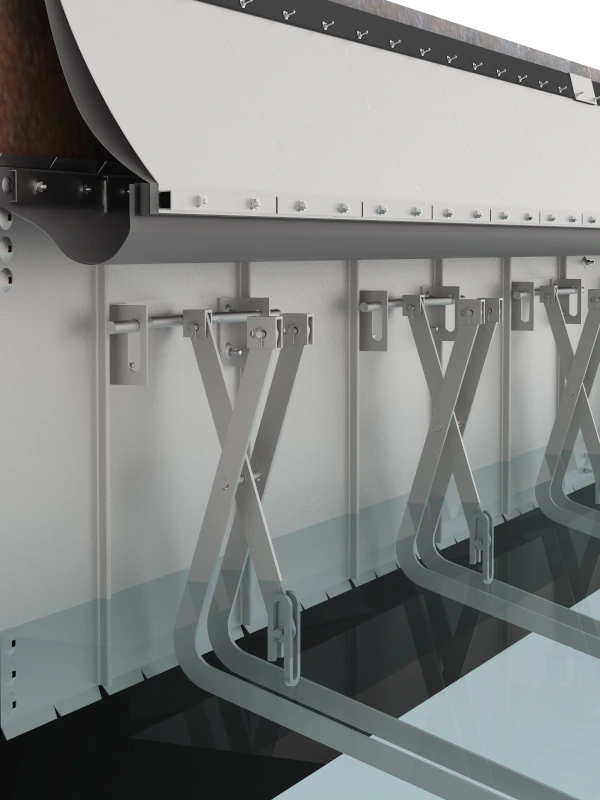

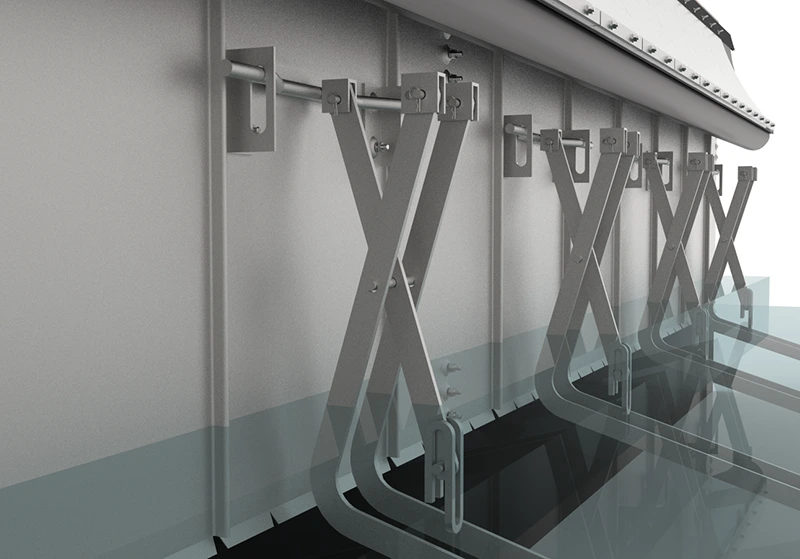

PRIMARY PANTOGRAPH SEAL

TankSeal®PT1

GENERAL INFORMATION

The Pantograph Primary Seal PT1 is the most widely used seal on Floating Roof Tanks and has been used on large tanks ranging storing virtually all Crude and Refined products.

BENEFITS

- In – service installation

- Complying with EPA Requirements

- Used in external roofs in compliance with API 650

- Unique design proved by extensive mechanical testing (e.g. evenly distributed pressure)

- Suitable for welded and riveted tank shells.

- Compatible with stored products

- Maximising usable tank capacity

- Primary fabric seal (selected for mechanical durability and chemical stability with the product)

- Easy to install, repair, inspect (all components are accessible from above)

DESIGN & CONSTRUCTION

The weighted pantograph system ensures that the sealing ring is held in constant contact with the tank shell.

The sealing ring is designed with flexures built into the sheets at intervals of approximately 550 mm. to ensure conformity with the tank shell and allow expansion and contraction.

The sealing ring extends into the product to ensure vapor retention and above the rim to ensure rainwater drains on to the Pontoon.

The space between the sealing ring and the roof is closed by a vapor-tight flexible continuous seal material. Shunts are used at intervals of 3 meters or less to maintain electrical continuity between the roof and the tank shell.

RECOMMENDED VAPOR MEMBRANE

- CALCIUM SILICATE: 1.9 mm thick. It complies with DIN 22118, DIN 22100 (Part 1) and the Health and Safety Committee Guide of Shell. Meets the LASTFIRE 6.1 specifications. 85% compatible with aromatic products.

- PTFE (Teflon): 0.45 mm thick. That comply with DIN 22118 and DIN 22100 (Part 1). Meets the LASTFIRE 6.1 specifications. 100% compatible with aromatic products.

- POLYURETHANE (PU): from 0.4mm to 1 mm thick. 70-100% compatible with aromatic products.

STANDARDS

API-650

NFPA “National Fire Protection Agency”.

AISI Stainless Steel Cold Formed Structural Design Manual.

AWWA D-100.

EUROCODE

TECHNICAL DATA

- Rim Spaces: Normally 200 mm. ± 100 mm. is the standard but the seal design can be modified to suit larger nominal rim space.

- Aromatic Service : 100%

MATERIAL SPECIFICATION

-

Continuous Seal: Teflon/Fiberglass, Calcium Silicate, Urethane, Polyurethane.

-

Sealing Ring: Galvanized / Stainless Steel

-

Service life: 10-25 years

-

Typical Weight: ≈ 45kg per linear meter.