SECONDARY COMPRESSION PLATE SEAL

TankSeal®CPI

GENERAL INFORMATION

The Secondary Seal is a rim mounted system suitable for floating roof tanks of all sizes storing all grades of crude and refined products.

BENEFITS

- In – service installation

- Complying with EPA Requirements

- Used in internal roofs in compliance with API 650

- Unique design proved by extensive mechanical testing (e.g. evenly distributed pressure)

- Suitable for welded and riveted tank shells.

- Compatible with stored products

- Maximising usable tank capacity

- Primary fabric seal (selected for mechanical durability and chemical stability with the product)

- Easy to install, repair, inspect (all components are accessible from above)

DESIGN & CONSTRUCTION

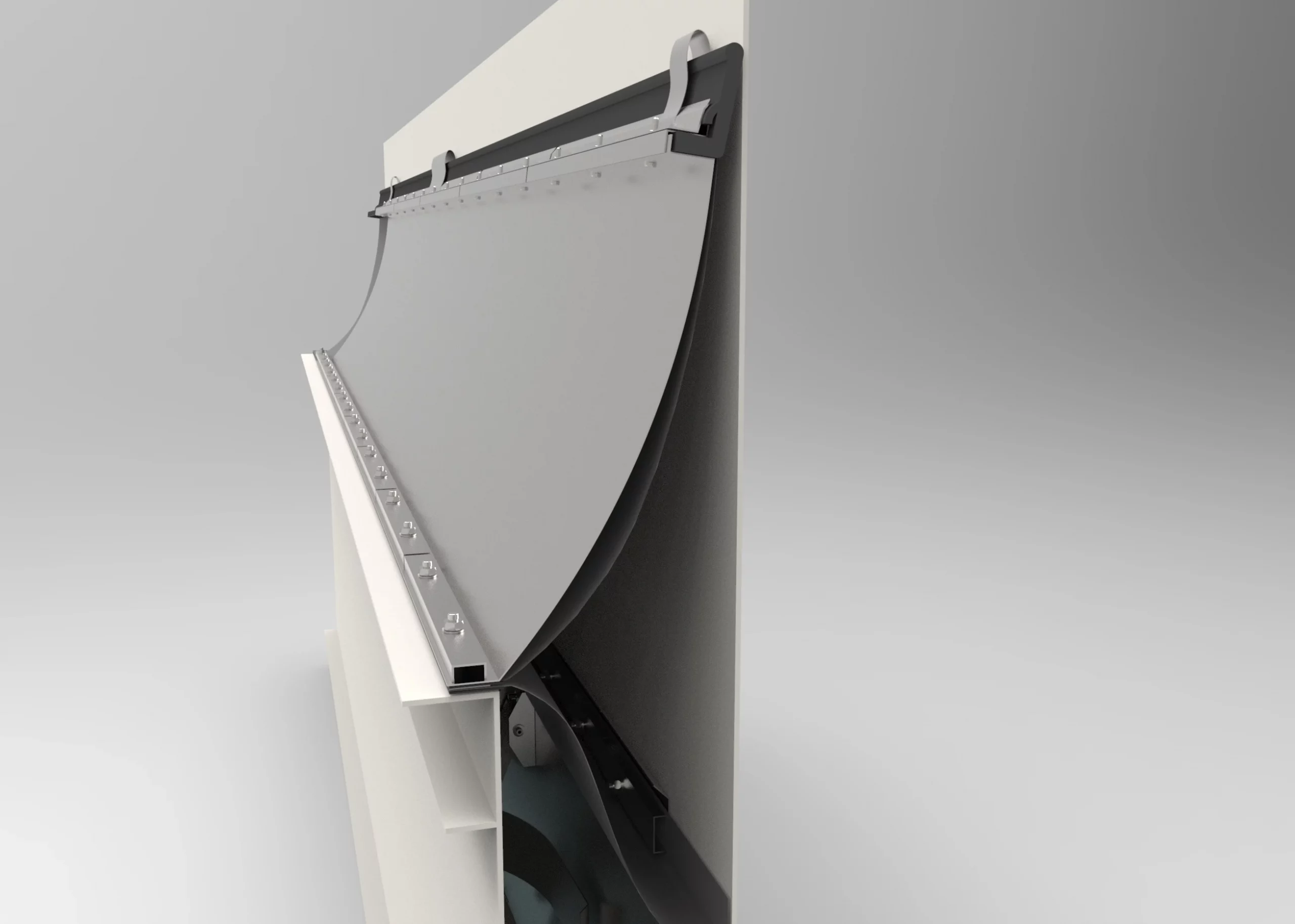

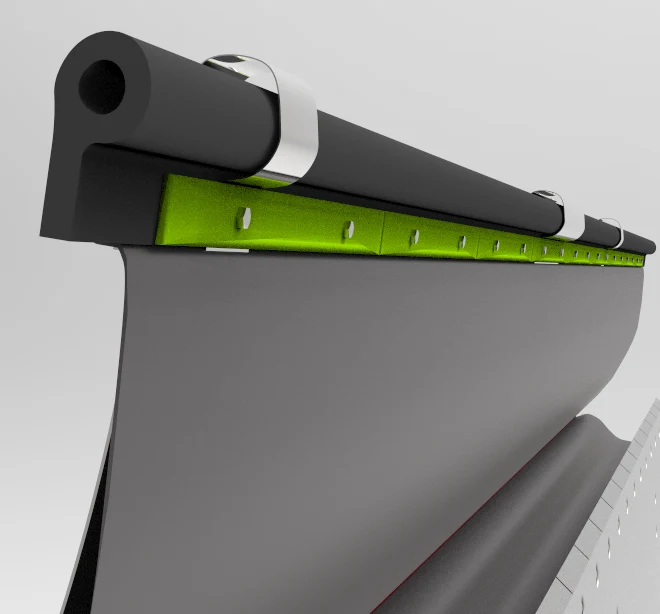

The CPI Seal is designed to be installed whilst the tank is in service. The seal incorporates a compression plate, synthetic rubber wiper and vapour barrier membrane. The compression plate can be made from either galvanised steel or stainless steel.

The vapour barrier membrane is normally manufactured from polyurethane-coated nylon fabric with very low vapour permeability properties. PVC Nitrile, PTFE/Teflon or Firestop materials may be adopted depending of customers’ requirements.

The seal design is such that all the fixings are on the outside of the seal; i.e. the tank shell side is completely smooth. The smooth outside surface of the seal ensures that the risk of damage is minimized if the roof is floating above the tank shell.

The seal can be fixed to either a vertical upstand or horizontal angle. The dimensions of the compression plate can be varied to suit a wide range of nominal rim spaces.

RECOMMENDED VAPOR MEMBRANE

- CALCIUM SILICATE: 1.9 mm thick. It complies with DIN 22118, DIN 22100 (Part 1) and the Health and Safety Committee Guide of Shell. Meets the LASTFIRE 6.1 specifications. 85% compatible with aromatic products.

- PTFE (Teflon): 0.45 mm thick. That comply with DIN 22118 and DIN 22100 (Part 1). Meets the LASTFIRE 6.1 specifications. 100% compatible with aromatic products.

- POLYURETHANE (PU): from 0.4mm to 1 mm thick. 70-100% compatible with aromatic products.

STANDARDS

API-650 Ap. G

NFPA “National Fire Protection Agency”.

AISI Stainless Steel Cold Formed Structural Design Manual.

AWWA D-100.

EUROCODE

TECHNICAL DATA

- Rim Spaces: Normally 200 mm. ± 100 mm. is the standard but the seal design can be modified to suit larger nominal rim space.

- Aromatic Service : 100%

MATERIAL SPECIFICATION

-

Continuous Seal: Teflon/Fiberglass, Calcium Silicate, Urethane, Polyurethane.

-

Compression Plate: Galvanised or Stainless Steel

-

Clamp Channels: Galvanised or Stainless Steel.

-

Wiper: Synthetic rubber, high tensile strength, good wear resistance, excellent weathering.

-

Service life: 10-20 years

-

Typical Weight: ≈ 15 kg per linear meter.